What’s New in Telehandlers?

As the need for jobsite efficiency continues to grow, so does the equipment that is being used. There is a continued goal to improve productivity and safety which has influenced the improvements with JLG® and SkyTrak® product development. As a trusted provider of JLG equipment, All Access Services and our clients continue to rely on improved solutions that will deliver tangible benefits to clients.

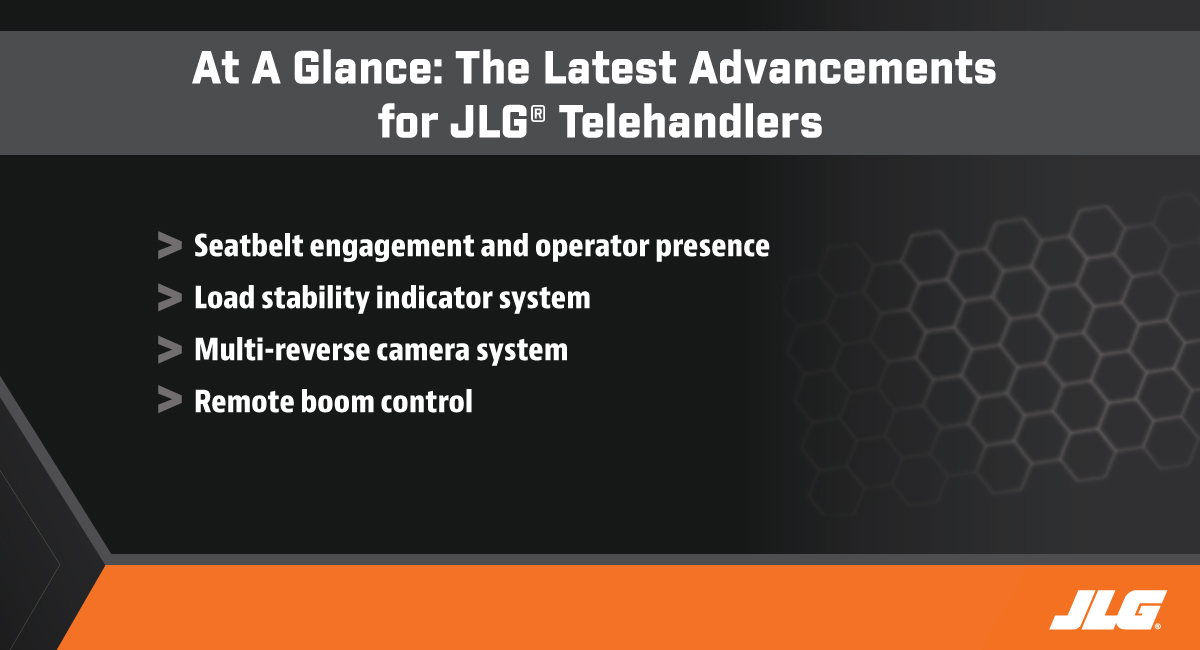

Latest Telehandler Features

Seatbelt Engagement and Operator Presence

A Seatbelt Engagement and Operator Presence option for JLG® 742, 943, 1043, 1055 and 1255 telehandler models. This new system includes seatbelt engagement assurance operator presence functionality along with high visibility orange seatbelts, uses visual and audible alarms and limits machine functions to enhance safety during equipment operation.

The seatbelt engagement assurance produces a visible and audible alarm that will activate when an operator is seated and unbuckled. Example: When the operator is seated with the ignition key on, alarms will be activated immediately and continuously and stop when the operator leaves the seat or turns off the ignition. The goal is to alert and remind operators and will not prevent engine start-up or hydraulic functions, very similar to a seatbelt in standard vehicles.

Operator presence functionality prohibits the engine to start and hydraulic functions if the operator is not present. If the system also detects a loss of seat pressure during operation, one of the following will happen:

1.If the park brake is engaged and the transmission is in neutral, the hydraulic controls are disabled. They are enabled upon a return to a seated position. If the park brake is disengaged and transmission is in neutral, hydraulic controls are disabled and the cabin alarm sounds continuously until a return to seated position in which the controls are enabled and the alarm stops.

2. If the park brake is disengaged and the transmission is in a forward or reverse position, hydraulic controls are disabled, the alarm sounds, and the transmission shifts to neutral. Once the operator has returned to a seated position, hydraulic controls are enabled and the alarm stops. The transmission will need to be returned to neutral to allow the system to reset before forward or reverse travel.

Load Stability Indication (LSI) System

This system aids operators by helping them to remain within the longitudinal or forward load capacity of the telehandler. It’s comprised of four primary components:

The first is a sensor attached to the rear axle, which is able to measure the weight applied to the rear axle of the vehicle. The sensor on the rear axle provides the rear axle load measurement to the vehicle control system.

The second part of the LSI system is the vehicle control system, which is the brain of the vehicle, collecting and transmitting data and commands to many parts of the vehicle. The vehicle control system sends data to the LSI display in the cabin of the vehicle.

The third part of the LSI system is the LSI display that provides the operator a visual indication of the forward stability status of the vehicle. There are six levels of indication in the display, progressing from green (load within capability) to orange (load capability nearing limit) to red (load capability at the limit). If the forward load capability of the vehicle is reached, a red lamp is illuminated on the display. When this happens, an audible alarm is activated, and the vehicle control system will stop and prevent further activation of many of the vehicle hydraulic implement functions. The only implement functions available to the operator to correct the stability of the vehicle are retract boom (in) and lift boom (up). When stability of the vehicle has been improved, the audible alarm will turn off and the display will return to orange.

The fourth and final part of the LSI system is the LSI Override Switch, which the operator may choose to use in order to continue operating the vehicle with the red lamp illuminated and hydraulic implement functions inhibited.

Backup camera technology — The JLG multi-reverse camera system can help operators see a broader area on the backside of the machine, giving operators more confidence when backing up. This feature increases job site awareness by displaying multiple views from behind the machine — left, right, and rear.

Boom control technology — JLG remote boom control enables operators to control the telehandler’s boom from outside the cab. This feature provides operators with improved visibility during load placement.

With 3 locations to serve you in the Los Angeles, Orange, Riverside and San Diego Counties… we continue to grow every year and stand by our motto no matter what… Our Motto, bill only what we quoted, always be on time and to have the highest quality most reliable equipment on the market! We promise to get you there! Any place, Anytime... ANYWHERE.

Serving ALL of Southern California!